| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Wanshida

Model Number : Y83-315

Certification : ISO9001,CE

Place of Origin : Jiangsu,China

MOQ : 1set

Price : Negotiable

Payment Terms : Western Union,T/T,L/C

Supply Ability : 30 sets/month

Delivery Time : 30days

Packaging Details : Sea Worthy

Product Name : Briquetting Press

Model : Y83-315

Nominal Force(KN) : 3150

Power(KW) : 22

PLC : Simens or Mitsubishi

Operation : PLC automatic

Usage : Waste Metal Recycling Yard

Capacity : 1200kg/h Cast iron sawdust

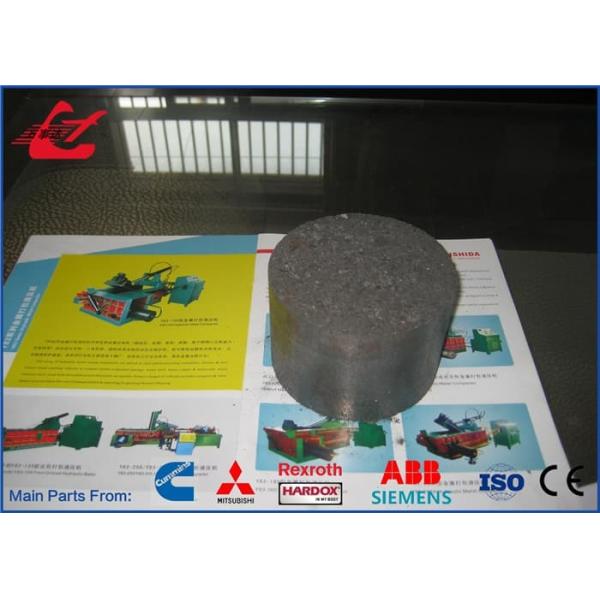

Metal Briquetting Press is a high-efficiency hydraulic forming equipment specifically designed for processing loose scrap materials generated during metal machining processes, such as cast iron chips, steel chips, copper chips, and aluminum chips. This series of machines utilizes high-tonnage hydraulic pressure to compress loose metal chips into high-density, regularly shaped briquettes (or cylindrical blocks), significantly reducing waste volume (by up to 80% or more) and markedly lowering transportation and storage costs. Simultaneously, it provides ideal furnace feed for smelting recycling, improving furnace efficiency and reducing melt loss. The equipment features a robust structure and stable operation, making it an ideal choice for metal recycling industries, machining workshops, and foundries to achieve waste valorization and green production.

| Model | Nominal Pressure (kN) | Briquette Size (mm) | Pressure on the bale | Power (kW) | Capacity |

|---|---|---|---|---|---|

| Y83-315 | 3150 | Ø120 x 180 | 278MPa | 22 | 800-1200kg/h Cast iron sawdust |

Q1: How much metal chips can a briquetting press process per hour?

A: The processing capacity varies depending on the material type, initial looseness, and machine model. For example, the Y83-315 model can process approximately 1200-1500 kg/hour of cast iron chips.

Q2: What is the approximate density of the briquettes after pressing?

A: The density of cast iron chip briquettes typically reaches 5.0-6.5 tons/cubic meter, depending on the pressure and material characteristics.

Q3: Does the equipment require a special foundation for installation?

A: Yes. Due to the enormous pressure generated during operation, a sturdy concrete foundation is required (we provide foundation drawings) to ensure operational stability and safety.

Q4: Can it process wet chips containing coolant or oil?

A: Yes. However, for materials with high oil content, preliminary deoiling is recommended to achieve optimal briquetting results and prevent potential contamination of the hydraulic system by oil.

Q5: How is after-sales service supported?

A: WANSHIDA provides global after-sales service, including installation guidance (remote or on-site), operation training, one-year warranty, and lifelong technical support and spare parts supply.

|

|

22kw Scrap Briquetting Press 315t Metal Recycling scrap baling press machine 1.2T/h Images |